From Raw Materials to a Glass Bowl

|

The night before, the glass is prepared by pouring glass into the melting furnace. The raw material consists mostly of sand but also contains additives such as lime and soda. For eight hours at 1220 degrees Celcius, the amount is melted down into glass that is completely clear and bubble-free.

To be able to work with the glass, the oven temperature is lowered to 1100 degrees and the glass becomes as soft as honey. The glass is caught in a lump at the end of an iron bar pipe and rolled in broken colored glass that gets stuck in the hot lump. Glass is colored by metal oxides, 1 to 2 grams of metal is often enough for 1 kilo of glass. The working temperature is between 600 to 1000 degrees. At 500 degrees, the glass becomes hard as rock. This means that the glass needs to be heated often in a heating oven. |

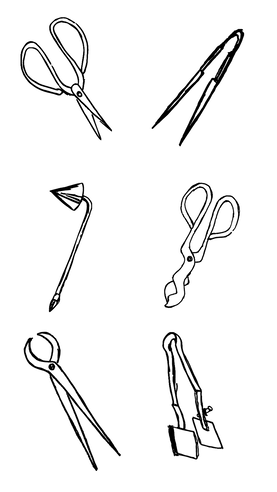

The glass is shaped with the help of tools such as wooden buckets and soaked newspaper. The steam that arises when in contact with the hot glass creates a protective layer on which the glass can slide smoothly. With the help of the tools, the glassblower ensures that the bubble that is inflated inside the glass comes in the right place and becomes even.

A metal pair called cutting shears is used to cut a narrow waist that makes it possible to knock off the glass from the iron bar pipe. Then the glass is attached to a new iron bar that holds it from the other direction. Finally, the cutting shears are used to widen the hole that is formed when the glass is knocked off.

When the glass is opened, it becomes a bowl. It is then knocked off and placed in a cooling oven where it slowly cools overnight from 500 degrees to room temperature. The next day, the glass bowl is ready and ready to use.

A metal pair called cutting shears is used to cut a narrow waist that makes it possible to knock off the glass from the iron bar pipe. Then the glass is attached to a new iron bar that holds it from the other direction. Finally, the cutting shears are used to widen the hole that is formed when the glass is knocked off.

When the glass is opened, it becomes a bowl. It is then knocked off and placed in a cooling oven where it slowly cools overnight from 500 degrees to room temperature. The next day, the glass bowl is ready and ready to use.

Watch glassblowing process videos on our Instagram @stockholmsglasbruk

|

|